An air compressor is a device that converts power (usually from an electric motor, diesel engine, or gasoline engine) into potential energy stored in compressed air. This compressed air can then be used in various applications, such as powering tools or inflating tires.

Air compressors come in different sizes and designs, ranging from small portable units to large stationary units that are capable of producing high volumes of compressed air. They can also be categorized into two types: positive displacement compressors and dynamic compressors.

Positive displacement compressors work by filling and emptying a chamber, such as a piston or screw, to compress the air. Dynamic compressors, on the other hand, use rotating impellers to accelerate and then decelerate the air, increasing its pressure.

Air compressors are widely used in many industries, including manufacturing, construction, automotive, and aerospace. They are also commonly found in households and garages, where they can be used for tasks such as inflating tires, powering air tools, and blowing debris.

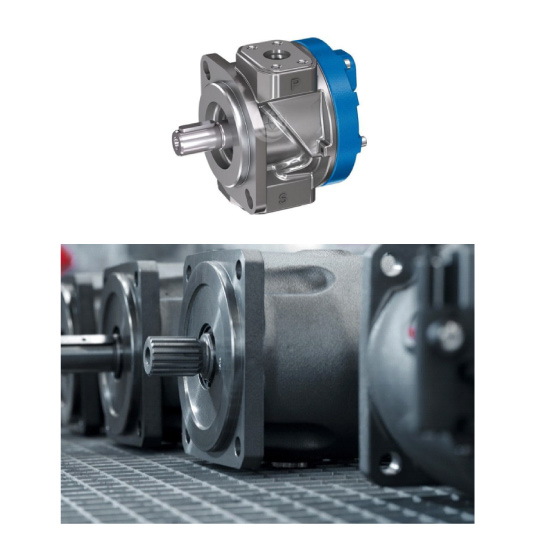

A hydraulic pump is used in many industrial and commercial applications to convert mechanical energy into hydraulic energy.

The hydraulic pump works by moving hydraulic fluids through pipes and hoses. Hydraulic pumps are known for their ability to generate high pressure for transporting hydraulic fluids through pipes and hoses. The hydraulic fluid is typically moved by an electric or diesel engine.

A hydraulic pump consists of several parts, including the outer shell, motor, crankshaft, control valve system, piston, pipes, and hoses. The efficiency of a hydraulic pump depends on several factors, including the size of the pump, operating pressure, and flow rate.

Hydraulic pumps are commonly used in many applications, including hydraulic lift systems, heavy equipment, agricultural machinery, and industrial control systems. The type of hydraulic pump used is usually chosen based on the size of the load, operating pressure, and required flow rate.

Rubber parts for trucks refer to various components made of rubber materials that are used in trucks. These parts can include items such as engine mounts, suspension bushings, hoses, belts, gaskets, seals, and other components. They are designed to absorb shock, reduce vibration, and provide insulation between different parts of the truck. Rubber parts are important for ensuring the smooth and safe operation of the truck, as they help to reduce wear and tear on other parts and prevent damage from excessive vibration or movement. Proper maintenance and replacement of worn rubber parts is essential to ensure the longevity and reliability of the truck.

Hoses for trucks are flexible tubes made of rubber or other materials that are used to transfer various fluids, such as air, water, fuel, oil, and hydraulic fluid, between different components of the vehicle. They are used in a variety of systems, including the engine, cooling system, brake system, and hydraulic system. Hoses are designed to be durable and resistant to high temperatures, pressure, and other environmental factors. They come in different shapes and sizes to fit specific applications in the truck. Regular inspection and maintenance of hoses are important to prevent leaks and ensure the proper functioning of the vehicle's systems.