Brake pads are a crucial component of the braking system in vehicles and other machinery. They are made up of steel backing plates with friction material attached to the surface that comes in contact with the brake rotors.

When the brakes are applied, the brake pads are squeezed against the rotating rotor, which generates friction and converts the kinetic energy of the vehicle into thermal energy. This process slows down and ultimately stops the vehicle.

As the brake pads come into contact with the rotor, a small amount of the friction material is transferred onto the rotor, leaving a dull grey coating on it. Over time, this coating can build up and affect the performance of the brakes. Therefore, it is important to regularly inspect and replace the brake pads when needed.

Brake pads come in different types and materials, such as ceramic, metallic, and organic. Each type of brake pad has its own advantages and disadvantages in terms of cost, durability, noise, and performance. The type of brake pad used depends on the specific application and requirements of the vehicle or machinery.

Air brake systems are commonly used in heavy-duty vehicles such as trucks, buses, and trains to provide reliable braking power. The air brake system works by converting compressed air into mechanical energy to operate the brakes.

The main components of an air brake system include the air compressor, air dryer, air reservoirs, brake chambers, and brake lines. The air compressor compresses the air and sends it to the air dryer, which removes moisture and contaminants from the air before it is stored in the air reservoirs. The air reservoirs store the compressed air and supply it to the brake chambers when needed.

The brake chambers are located at each wheel and use the compressed air to push a piston that applies the brakes. The brake lines connect the brake chambers to the air reservoirs and control valves, which regulate the pressure and flow of air to the brake chambers.

Air brake systems are preferred in heavy-duty vehicles because they provide consistent braking power, even in extreme conditions such as wet or icy roads. Additionally, air brakes have a fail-safe system that automatically applies the brakes if there is a loss of air pressure in the system, ensuring the vehicle comes to a safe stop.

However, air brake systems require regular maintenance to ensure their proper function. This includes checking for air leaks, maintaining proper air pressure in the system, and replacing worn or damaged components. It's important to follow the manufacturer's recommended maintenance schedule and to have the air brake system inspected by a qualified technician regularly to ensure its safety and reliability.

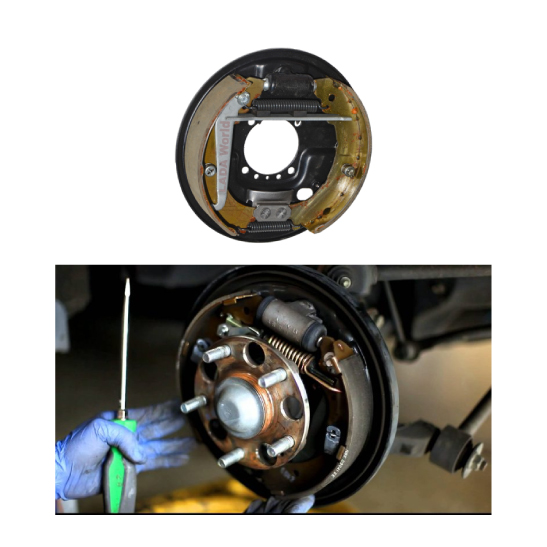

A brake ratchet is a mechanism used in some types of brakes to prevent the brake from releasing unintentionally. It consists of a ratchet wheel and a pawl, which engages with the teeth on the wheel to prevent it from turning in the wrong direction. When the brake is applied, the ratchet is disengaged, allowing the wheel to turn freely. When the brake is released, the pawl engages with the ratchet wheel, preventing it from turning backwards and keeping the brake engaged. The brake ratchet is commonly used in industrial and heavy equipment applications to ensure safe and reliable operation of the equipment.

It is a braking system part located in the rear tires of the vehicles and helps the vehicle to stop by slowing down the rotation speed. This part, made of cast iron, compresses from the center point to the outer point, thus increasing friction. This slows down the rotational speed of the wheels.

A brake disc, also known as a rotor, is a component of the braking system that works in conjunction with the brake pads to slow or stop a vehicle. It is typically made of cast iron or a composite material and is mounted to the wheel hub. When the brake pedal is applied, hydraulic pressure causes the brake pads to press against the brake disc, creating friction and slowing down the vehicle. Brake discs are an important safety feature in vehicles and require regular maintenance and replacement when worn or damaged.

When it is asked what is the hub, it is located on the vehicle as a carrier piece attached to the axle on the wheels of the vehicle. With the hub, we can easily understand the rotation process of the wheel in general.